Pneumatic vibration isolation systemAP series

You can compose the most suitable vibration isolation system fitted to your precise machines at low cost.

It is important that vibration isolation system has flexibility as well as excellent performance.Because it is the best way to install vibration isolation system that is tuned in on these precise machines.That is "AP Series" vibration isolation system that can be immediately adapted to your needs. In addition to the capacity for vibration isolation, "AP Series" has system extensibility too.This vibration isolation system, "AP Series" materializes an ideal vibration isolation environment.

- Passive

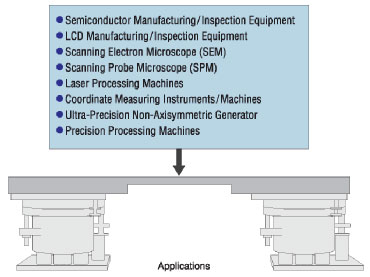

Business Fields

- For Measurement

- For Semiconductor

- Unit type

Features

The pneumatic vibration isolation systems of Meiritsu have stirring performance in actual achievement of the technology.

We adopted the pneumatic system with a lot of actual achievement in the variety field from microscopy or laser application technology to semiconductor manufacture/inspection devices.

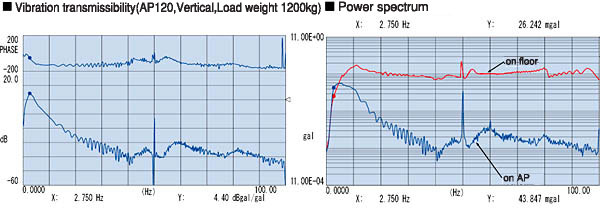

We assure you that you get excellent vibration isolation performance in the wide band of frequency from 3 Hz to hundreds Hz.

And rubber installed in the lower part of air spring protects the precise mechanism of a mounted machine in case of supply stop of air.

"AP Series" is a unit type of a versatile system.

When a vibration isolation system is installed in a machine, it is required to occupy less space of the machine.

"AP Series" is a compact shaped unit type of isolation system that is composed of an air spring and a mechanical leveling valve.

You can install "AP Series" in a device without modifying the structure of the device on a large scale and can get good vibration isolation performance.

All the height of "AP Series" is standardized to 185mm.

All the height of "AP Series" is standardized to 185mm. Even if you have to increase or decrease the mass of your machine, you can fit the other type of "AP Series" without changing the height of installing space of your machine.

"AP Series" covers a wide range of loading mass.

Abundant variety and purpose of precise machines that need vibration isolation system grow increasingly diverse. In order to respond to the requirement, we provide 11 types of "AP Series" from "AP-80" to "AP-380". You can select suitable one from "AP Series" even if a precision machine has a weight of hundreds kilograms or more than 10 tons.

High performance for a movement of the load.

In case of works handling, flat panel transferring, and stage movement of an automatic processing/measurement machine, position repeatability is required even when supported by air springs as elastic bodies.

"AP Series" has a high sensitive leveling valve as its standard developed by Meiritsu. The positioning repeatability is within +/- 200 micrometers.

And it is often said that the faster stages moves, the more problems of shakiness occur. These are as we say pitching, yawing, or rolling.

If you choose optional two-step-type of leveling valves, you can shorten the convergence time.

And you can get positioning repeatability within +/-100 micrometers as the limit sensitivity of passive type of isolation system.

Be sure to make contact with us in advance if you predict that convergence time causes some problems.

You can use "AP Series" in clean rooms too.

When "AP Series" is used in a high level clean room, you can choose leveling valves for clean room that can exhaust air to put together into a tube for evacuation.

Please contact us about details because it is a special order. And note that two-step-type of leveling valve is not available for clean rooms.

Notice when selecting a type of "AP Series" or designing of a device in which "AP Series" will be installed.

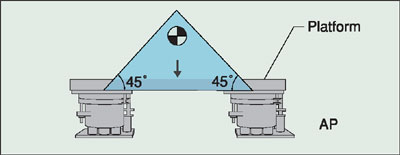

- Lager span between air springs are required.

- Adjust the center of gravity position of loading devices including the loading board within the area of pale blue triangle (in back cover of Japanese pamphlet).

- Select "AP Series" in consideration of the most one-sided load condition when works move. And consult us in advance if there is any problem of shakiness of a loading board or its convergent time. We are pleased to advice if you give us information such as mass, velocity, acceleration, and stroke of the moving object.

- There should be 10mm or more clearance when you set up a cover or so on the circumference of the loading board.

- When you move a device in which vibration isolation systems are installed, be sure to confirm that the loading board and pedestal/a base-plate are clamped.

- Select a higher stiffness type of a loading board and pedestals/a base-plate in order to achieve a full performance of vibration isolation.

- Standard type of "AP Series" consists of four air springs. However, it is possible for you to select other type of "AP Series" that consists of six, eight, or more air springs. If you have some idea, please contact with us

Specifications

- SPECIFICATIONS

| Model | AP-80 | AP-100 | AP-120 | AP-140 | AP-160 | AP-180 |

|---|---|---|---|---|---|---|

|

Natural frequency | 2.5-3.0Hz (Vertical, Horizontal) | |||||

|

Vibration isolation method | Air Suspension | |||||

|

Damping method | Dumping by Orifice | |||||

|

Leveling Method | Automatic Leveling by mechanical air valve (Positioning Tolerance +/-200micrometers) | |||||

|

Dimensions (mm) |

170x170 x185 |

180x180 x185 |

200x200 x185 |

210x210 x185 |

240x240 x185 |

250x250 x185 |

|

Mass (kg/unit) | 10.5 | 14 | 15 | 19 | 21 | 27.5 |

|

Payload (kg/4units) | 560 | 880 | 1200 | 1700 | 2200 | 2800 |

|

Supplied Air Pressure (MPa) |

0.40-0.70MPa (Air source: Compressed air by air compressor, relieving a factory's piping of its air, or liquid) | |||||

| Model | AP-200 | AP-230 | AP-270 | AP-330 | AP-380 |

|---|---|---|---|---|---|

|

Natural frequency | 2.5-3.0Hz (Vertical, Horizontal) | ||||

|

Vibration isolation method | Air Suspension | ||||

|

Damping method | Dumping by Orifice | ||||

|

Leveling Method | Automatic Leveling by mechanical air valve (Positioning Tolerance +/-200micrometers) | ||||

|

Dimensions (mm) |

260x260 x185 |

300x300 x185 |

320x320 x185 |

370x370 x185 |

430x430 x185 |

|

Mass (kg/unit) | 32 | 43.5 | 52 | 67.5 | 90 |

|

Payload (kg/4units) | 3600 | 4600 | 6400 | 9600 | 13000 |

|

Supplied Air Pressure (MPa) |

0.40-0.70MPa (Air source: Compressed air by air compressor, relieving a factory's piping of its air, or liquid) | ||||

Product Inquiry

Complete the form below and press the submit button.*We will respond via email as soon as possible.